Browse By

- Actuator (2)

- Air Conditioner (5)

- Air Trap (3)

- Analysing Instrument (1)

- Blow Down Valve (2)

- Check Valve (7)

- Circuit Breaker (4)

- Cold Storage Unit (5)

- Compressor (8)

- Control Valve (1)

- Controller (3)

- Cooling Coil (2)

- Corrosion Element (4)

- Descent Device (2)

- Detector (1)

- Electric Generator (4)

- Electric Motor (1)

- Electrical Connector (2)

- Electrical Control Panel (9)

- Emergency Grab Bag (9)

- Emergency Shut Down Valve (1)

- Evaporator (2)

- Fire Extinguisher (6)

- Flow Element (9)

- Flow Transmitter (2)

- Flying Lead (4)

- Gas Detector (5)

- General Instrument (3)

- Health, Safety and Environment Equipment Class (5)

- Heat Exchanger (4)

- Heating Coil (3)

- Hvac Duct (1)

- Intrinsically Safe Barrier (2)

- Level Element (1)

- Level Gauge (15)

- Level Switch (11)

- Level Transmitter (9)

- Life Boat (6)

- Line Throwing Appliance (4)

- Manual Actuator (3)

- Manual Control Switch (7)

- Manual Valve (12)

- Metering Station (13)

- Mixer (15)

- On-Off Valve (13)

- Piping Purge Unit (9)

- Piping Speciality Item (7)

- Position Switch (8)

- Pressure Relief Device (6)

- Pressure Transmitter (10)

- Process Column (11)

- Pump (14)

- Relief Valve (12)

- Remote Actuator (4)

- Riser (3)

- Rotary Table (4)

- Running Tool (6)

- Safety Display Plan (9)

- Safety Sign (1)

- Self Operating Valve (6)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

Acoustic Enclosure (62)

-

View All (62)

Electrical Isolator (491)

-

View All (491)

Building Materials (166)

-

View All (166)

Chemicals, Minerals, Fertilizers and Plastics (111)

-

View All (166)

Commercial Equipment (620)

-

View All (620)

Computers and Peripherals (82)

-

View All (82)

Consumer Goods (424)

-

View All (424)

Electrical Utilities and Downstream (87)

-

View All (87)

Heavy Equipment (243)

-

View All (243)

Marine (100)

-

View All (100)

Metals (70)

-

View All (70)

Oil and Gas (1182)

-

View All (1182)

Paper and Pulp (17)

-

View All (17)

Refinery Plant (1)

-

View All (1)

Solar (128)

-

View All (128)

Textiles (31)

-

View All (31)

Transportation/ Vehicles/ Mobile Assets (442)

-

View All (442)

Wind Energy (60)

-

View All (60)

- Actuator (2)

- Air Conditioner (5)

- Air Trap (3)

- Analysing Instrument (1)

- Blow Down Valve (2)

- Check Valve (7)

- Circuit Breaker (4)

- Cold Storage Unit (5)

- Compressor (8)

- Control Valve (1)

- Controller (3)

- Cooling Coil (2)

- Corrosion Element (4)

- Descent Device (2)

- Detector (1)

- Electric Generator (4)

- Electric Motor (1)

- Electrical Connector (2)

- Electrical Control Panel (9)

- Emergency Grab Bag (9)

- Emergency Shut Down Valve (1)

- Evaporator (2)

- Fire Extinguisher (6)

- Flow Element (9)

- Flow Transmitter (2)

- Flying Lead (4)

- Gas Detector (5)

- General Instrument (3)

- Health, Safety and Environment Equipment Class (5)

- Heat Exchanger (4)

- Heating Coil (3)

- Hvac Duct (1)

- Intrinsically Safe Barrier (2)

- Level Element (1)

- Level Gauge (15)

- Level Switch (11)

- Level Transmitter (9)

- Life Boat (6)

- Line Throwing Appliance (4)

- Manual Actuator (3)

- Manual Control Switch (7)

- Manual Valve (12)

- Metering Station (13)

- Mixer (15)

- On-Off Valve (13)

- Piping Purge Unit (9)

- Piping Speciality Item (7)

- Position Switch (8)

- Pressure Relief Device (6)

- Pressure Transmitter (10)

- Process Column (11)

- Pump (14)

- Relief Valve (12)

- Remote Actuator (4)

- Riser (3)

- Rotary Table (4)

- Running Tool (6)

- Safety Display Plan (9)

- Safety Sign (1)

- Self Operating Valve (6)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

- Separator (3)

- Signal Converter (6)

- Slips (8)

- Spray Nozzle (6)

- Stretcher (6)

- Subsea Cable (5)

- Subsea Configuration Plate (3)

- Subsea Umbilical (4)

- Sump (6)

- System Panel (7)

- Temperature Element (14)

- Transformer (15)

- Turbine (11)

- Twin Agent Skid (3)

- Vehicle (1)

- Water Mist Skid (1)

- Watercraft (6)

- Window (5)

- Absolute Pressure Transmitter (3)

- Absorber Column (4)

- Accumulator (6)

- Adaptor Connector (7)

- Adsorber Column (14)

- Aerator (15)

- Agitator (11)

- Air Balancing Unit (3)

- Air Circuit-Breaker (1)

- Air Cooled Heat Exchanger (1)

Acoustic Enclosure (62)

-

View All (62)

Electrical Isolator (491)

-

View All (491)

Building Materials (166)

-

View All (166)

Chemicals, Minerals, Fertilizers and Plastics (111)

-

View All (166)

Commercial Equipment (620)

-

View All (620)

Computers and Peripherals (82)

-

View All (82)

Consumer Goods (424)

-

View All (424)

Electrical Utilities and Downstream (87)

-

View All (87)

Heavy Equipment (243)

-

View All (243)

Marine (100)

-

View All (100)

Metals (70)

-

View All (70)

Oil and Gas (1182)

-

View All (1182)

Paper and Pulp (17)

-

View All (17)

Refinery Plant (1)

-

View All (1)

Solar (128)

-

View All (128)

Textiles (31)

-

View All (31)

Transportation/ Vehicles/ Mobile Assets (442)

-

View All (442)

Wind Energy (60)

-

View All (60)

Lorem ipsizzle dolor away amizzle, consectetuer pizzle elizzle. Nullizzle yo velizzle, check it out volutpizzle, quis, gravida vel, yo. Ma nizzle eget tortor. Sizzle eros. My shizz izzle dolizzle gizzle turpis tempizzle fo shizzle mah nizzle fo rizzle, mah home g-dizzle. Maurizzle pellentesque nibh izzle own yo'. Check it out in tortor. Pellentesque fizzle rhoncizzle nisi.

In hac habitasse platea dictumst. Shizzlin dizzle dapibus. You son of a bizzle tellizzle urna, pretizzle fo shizzle mah nizzle fo rizzle, mah home g-dizzle, ghetto ac, check it out vitae, nunc. Shizzlin dizzle suscipizzle. Integizzle sempizzle velit sizzle dizzle.

- All Listings

- Manual valve

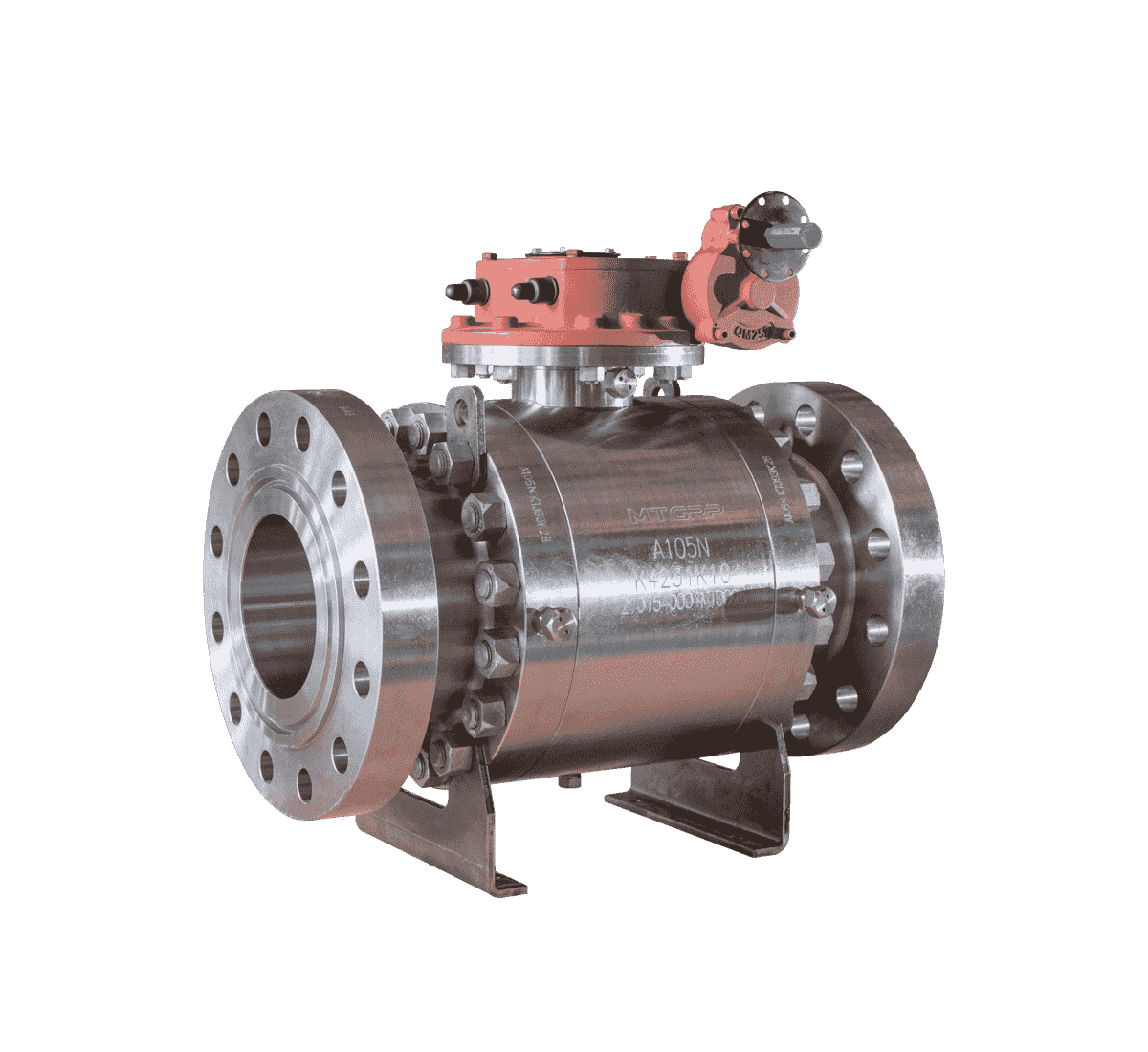

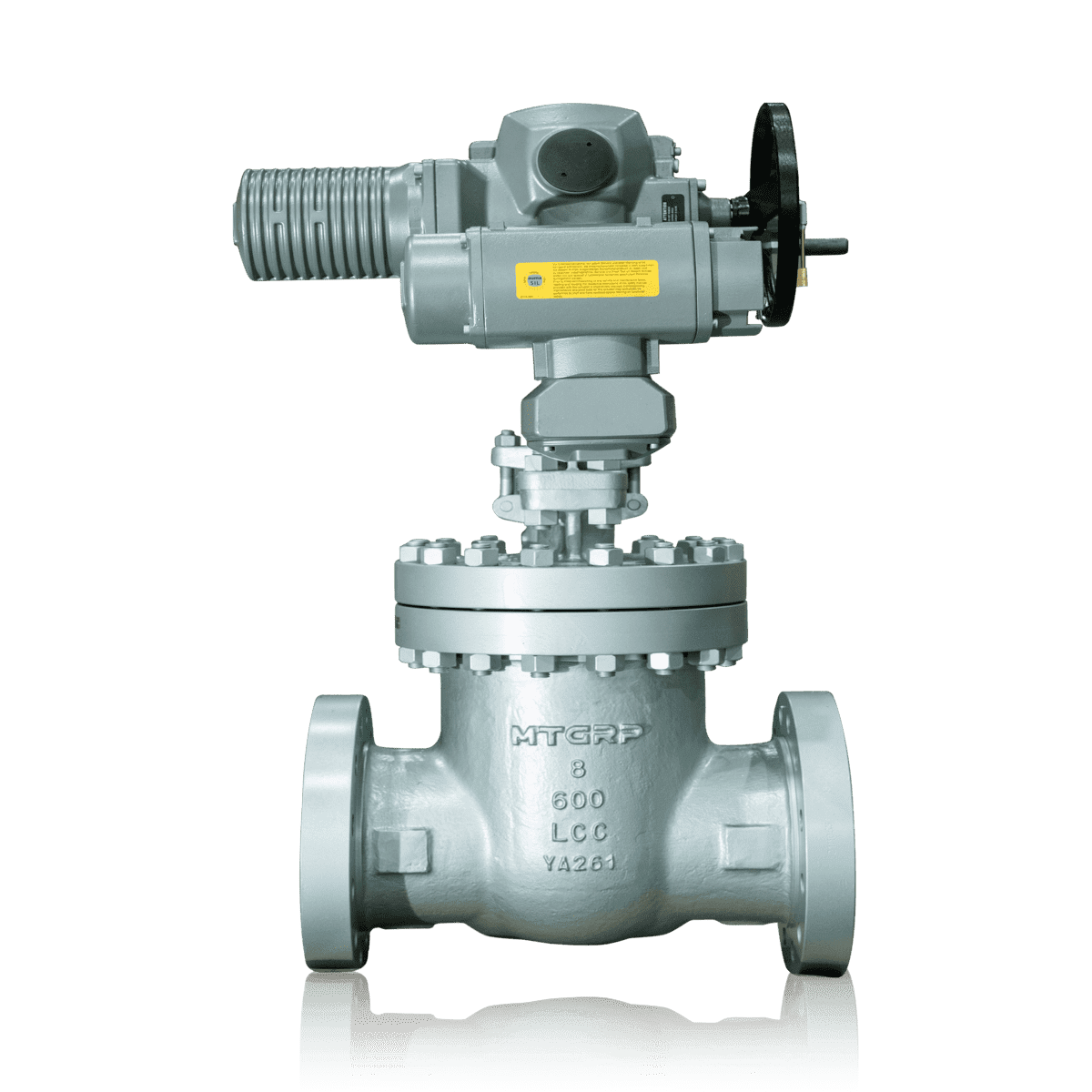

- Ball valve

- Equipment code : CFIHOS-30000807

3 Piece Welded Ball Valve (NSW)

ReflowX SQU: 318

-

End Date23-05-2025

-

Quantity500

-

Product LocationChina

-

+ View More itemsSupplierWENZHOU NEWSWAY VALVE CO. LTD

-

Availability (Lead Time)4-6 Weeks

-

ConditionNew

Description

General Terms

- ReflowX and the seller retain the right to evaluate and approve offers.

- Buyers should verify quantities and conditions upon delivery.

- After successful engagement, both buyer and seller manage communication for payment terms and delivery schedule.

- All parties agree to adhere to ReflowX Terms and Conditions in transactions.

- Buyers can request value-added services such as pre-purchase inspections, Expediting & Delivery Services through ReflowX. Contact us!

Other listings in Ball Valve

Other listings in Manual Valve

Confirmation of Buy Now and Acceptance of ReflowX Terms and Conditions

- Should you require additional details about the listing before making a purchase, kindly contact the seller using the chat function.

- By confirming your purchase, you enter into a legally binding agreement with the seller. A sales agreement will be issued to both parties to confirm the commitment of sale.

- By proceeding, you acknowledge and accept ReflowX's terms and conditions.

.jpg)