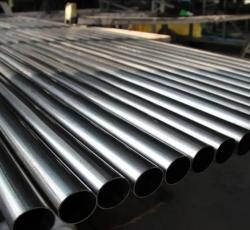

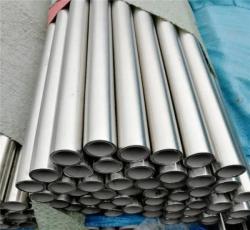

Overview of ASTM A213 Steel Pipe Scope: Purpose: ASTM A213 covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes, designated Grades T2, T5, T9, T11, T12, T22, T91, etc. Applications: These tubes are primarily used in high-temperature and corrosive environments where resistance to high pressure and temperature conditions is required. Manufacturing Process: Material: Alloy steel compositions as specified in the standard. Production: Tubes are typically produced by either hot finishing or cold finishing processes. Heat Treatment: Tubes may undergo heat treatment such as normalizing, quenching and tempering, or stress relieving as required by the standard. Specifications: Sizes and Dimensions: Tubes are available in various sizes with outer diameter and wall thickness specified. Grades: ASTM A213 specifies multiple grades of alloy steel tubes, each with specific mechanical properties and chemical compositions suitable for different service conditions. Testing and Inspection: Tubes are subjected to mechanical tests, hydrostatic tests, non-destructive tests (such as eddy current testing or ultrasonic testing), and other inspections to ensure compliance with ASTM standards. Types of Tubes: Boiler Tubes: Used in boilers for generating steam or hot water. Superheater Tubes: Used to raise the temperature of steam above its saturation point. Heat-Exchanger Tubes: Used for transferring heat between fluids or gases. Advantages: High Temperature Resistance: Suitable for applications involving high temperatures and pressures. Corrosion Resistance: Alloy compositions provide excellent resistance to corrosion in various environments. Strength and Durability: Designed to withstand harsh operating conditions in industrial settings. Standards and Compliance: ASTM A213: Standard specification for seamless ferritic and austenitic alloy-steel boiler, superheater, and heat-exchanger tubes. Compliance: Tubes conform to ASTM A213 requirements ensuring reliability and performance in critical applications. Conclusion: ASTM A213 steel pipes are essential components in industries requiring high-performance tubing for boilers, superheaters, and heat exchangers. Their alloy composition and stringent manufacturing standards ensure they meet the demanding requirements of high-pressure and high-temperature environments effectively.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

USD or choose a different currency.

USD or choose a different currency._1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)