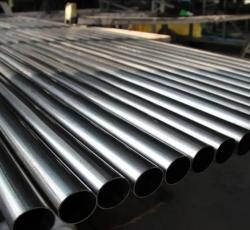

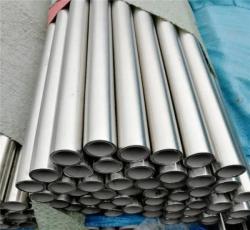

Seamless Steel Pipe Description: Seamless Steel Pipe is crafted from a solid round steel billet, which is heated and expertly formed into a hollow tube. The seamless pipe is then meticulously finished to meet precise dimensional and wall thickness specifications, available in sizes ranging from 1/8 inch to 32 inch OD. Material: Carbon Steel Seamless Pipes / Tubes: Carbon steel is an alloy composed primarily of iron and carbon. The carbon content in the steel influences its hardness, strength, elasticity, and ductility. Seamless carbon steel pipes are produced from solid steel ingots or billets, which are transformed into capillary tubes through a piercing process, followed by hot-rolling, cold-rolling, or cold-drawing. Manufacturing Process: In China’s steel industry, seamless carbon steel pipes hold significant importance. The manufacturing process begins with cutting round tube billets into approximately 1-meter lengths, which are then heated in a furnace to about 1200 degrees Celsius using hydrogen or acetylene fuel. Temperature control in the furnace is crucial for quality. Once heated, the billets are pierced using a tapered roll perforation machine, known for its high efficiency and ability to produce high-quality, large-diameter pipes. Following perforation, the round tubes undergo three-roll cross-rolling, rolling, or extrusion processes. The tubes are then sized by a high-speed rotary cone drill to determine the final diameter. After sizing, the pipes are cooled using water sprays in a cooling tower and subsequently straightened. Quality Control: Straightened pipes undergo rigorous internal testing using metal testing machines to detect any internal cracks, bubbles, or defects. Each pipe is subject to strict quality control measures, including manual inspection. Finally, the pipes are marked with spray paint for identification, including numbers, specifications, and production lot numbers. The finished pipes are then transported to the warehouse for storage. Applications: Seamless Steel Pipes are ideal for applications requiring high strength and durability, including in the oil and gas industry, construction, and various industrial sectors.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

USD or choose a different currency.

USD or choose a different currency._1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)