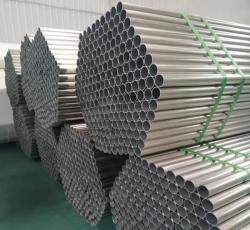

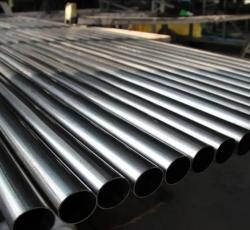

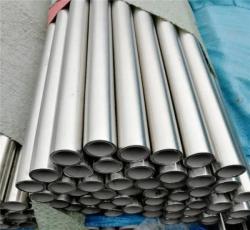

Overview of Stainless Steel Seamless Pipe Manufacturing Process: Extrusion and Drawing: The stainless steel billet is heated and pierced to form a hollow tube (ingot). Cold Drawing: The tube is then drawn through a series of dies to reduce its diameter and wall thickness while increasing its length. Annealing: Heat treatment process to relieve stress and improve ductility and corrosion resistance. Finishing: Ends are cut, deburred, and surface treated as per requirements. Advantages: Uniformity: Seamless pipes have consistent wall thickness throughout, suitable for high-pressure applications. Corrosion Resistance: Stainless steel’s inherent properties resist corrosion and oxidation. Strength: High mechanical strength suitable for structural and industrial uses. Cleanliness: Smooth surface finish minimizes risk of contamination in fluid transport applications. Applications: Industry: Used in chemical, petrochemical, pharmaceutical, food processing, and marine industries. Infrastructure: Structural components, heat exchangers, and conveyance systems. High-Temperature Services: Furnace components, heat exchangers, boilers, and superheaters. Standards and Specifications: ASTM A312: Standard specification for seamless, welded, and heavily cold worked austenitic stainless steel pipes. ASTM A790: Specification for seamless and welded ferritic/austenitic stainless steel pipe. DIN 17456: Standard for seamless circular tubes of stainless steels with austenitic-ferritic (duplex) grades. Types of Stainless Steel: Austenitic: Grades like 304, 316, 321; excellent corrosion resistance and formability. Ferritic and Martensitic: Grades like 410, 430; good mechanical properties and moderate corrosion resistance. Duplex and Super Duplex: Grades like 2205, 2507; high strength and improved resistance to stress corrosion cracking. Conclusion: Stainless steel seamless pipes are integral in industries requiring reliable, corrosion-resistant, and high-strength piping solutions. Their seamless construction ensures superior performance in critical applications where fluid integrity and durability are paramount.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

USD or choose a different currency.

USD or choose a different currency._1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)