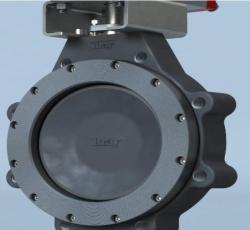

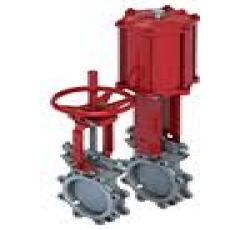

The Double Offset Butterfly Valve, often referred to as a high-performance butterfly valve, is an essential component widely utilized in water plants, power plants, steel mill smelting, chemical industries, water source projects, and environmental facilities. Serving as both a regulation and interception device, it excels in waterway pipelines where reliability and longevity are critical. Compared to concentric butterfly valves, the double offset variant offers superior resistance to high pressure, extended service life, and enhanced stability.

Key Features:

Versatile Application: Ideal for a variety of industries including water treatment, power generation, metallurgy, and chemical processing.

High Performance: Engineered for robust performance in demanding environments, ensuring reliable operation over extended periods.

Pressure Resistance: Suitable for pressure ratings ranging from Class150 to 300LB, capable of withstanding high-pressure applications.

Material Options: Available in materials such as WCB, LCB, CF8, CF8M, CF3, CF3M, providing corrosion resistance and durability.

Specifications:

Size Range: 2”~24”

Pressure Rating: Class150~300LB

Main Materials: WCB, LCB, CF8, CF8M, CF3, CF3M, etc.

Design and Manufacture Standards: API 609

Face-to-Face Dimension: API 609

Ends Connection: Options include Flange, Wafer, and Lug for flexible installation.

Inspection & Testing: Complies with API 598 standards to ensure quality and performance reliability.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

USD or choose a different currency.

USD or choose a different currency._1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)