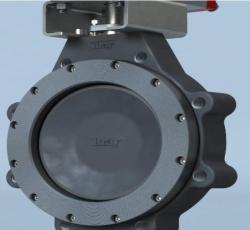

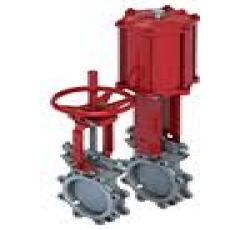

The Fire Safety Double Offset Butterfly Valve features a uniquely structured design, ensuring unparalleled sealing performance, broad operational versatility, minimal torque requirements, extended service life, and reliability in challenging environments. This series of high-performance double eccentric butterfly valves is crafted from a variety of robust materials, including NACE compliant and abrasion-resistant alloys. It is specifically engineered for applications involving cryogenic temperatures, steam, chlorine, oxygen, high vacuum, corrosive mediums, and low-temperature conditions.

Key Features:

Advanced Design: Incorporates a double eccentric configuration that reduces friction and wear, enhancing operational efficiency and longevity.

Superior Sealing: Utilizes soft-seal materials such as PTFE, RPTFE, PPL, and PEEK, ensuring reliable sealing performance under varying conditions.

Wide Temperature Range: Suitable for temperatures below 180℃ (T<180℃), making it versatile for a range of industrial applications.

Fireproof Design: Engineered to maintain integrity and functionality in fire-prone environments, meeting stringent safety standards.

Materials: Available in WCB, CF8, CF8M, CF3, CF3M, Monel, HC, and other durable alloys to suit diverse operational requirements.

Specifications:

Name: Fire Safety Double Offset Butterfly Valve

Size Range: 2”~60”, DN50-DN1500

Pressure Rating: ANSI 150LB-900LB, 1.0MPa~16.0MPa, JIS10K-40K

Casting Body: WCB, CF8, CF8M, CF3, CF3M, Monel, HC, etc.

Seals Material: PTFE, RPTFE, PPL, PEEK

Sealing Surface: Soft Sealed

Working Temperature: T<180℃

Design and Manufacture Standards: API609, EN593

Face-to-Face Dimension: API 609, ASME B16.10, EN558-1

Ends Connection: Wafer

Inspection & Testing: API598, EN12266

Certifications: CE, ISO9001, API, ensuring compliance with international quality and safety standards.

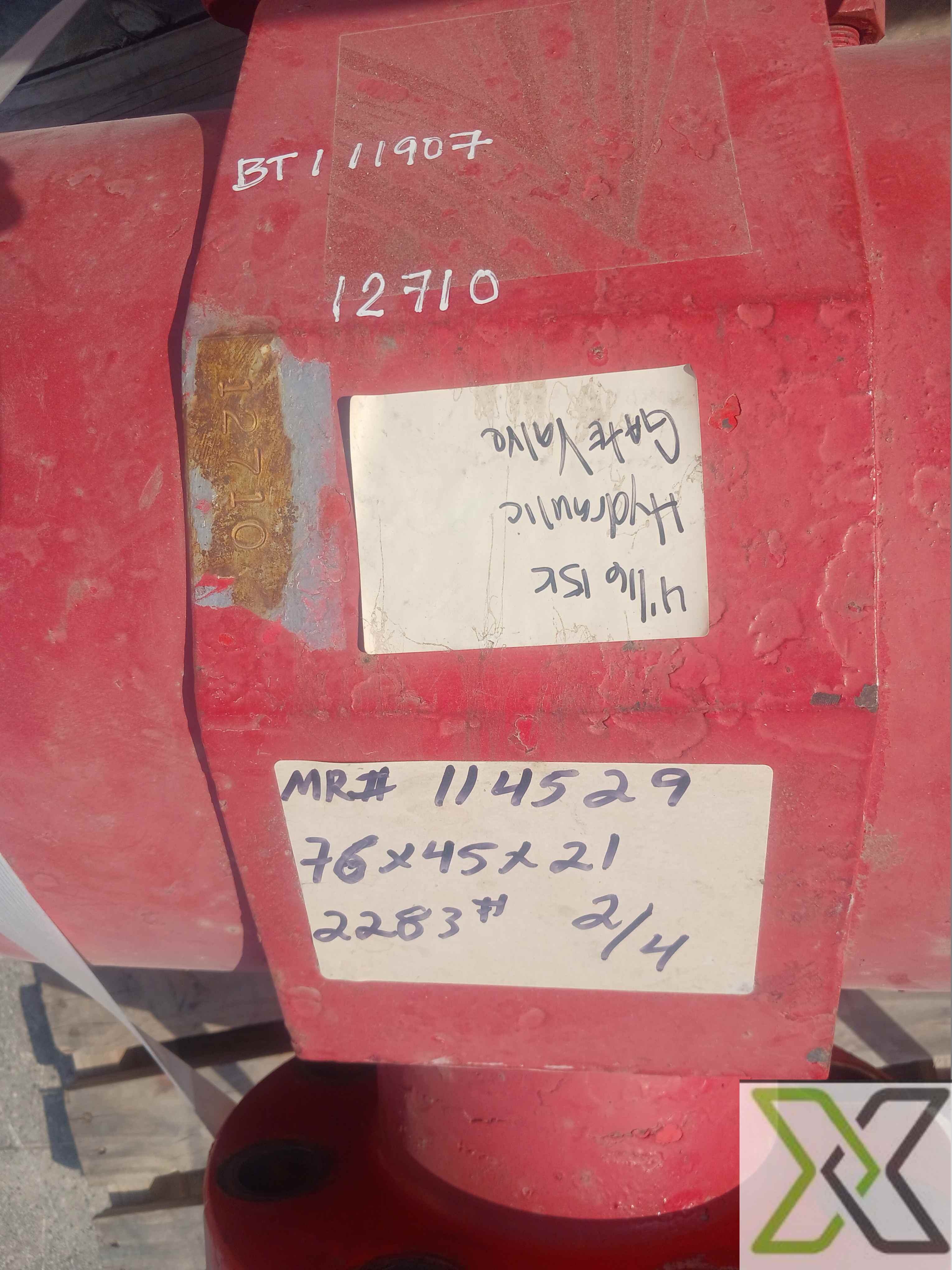

Operation: Compatible with various actuation methods including Lever, Bare Shaft, Electric, Pneumatic, or Hydraulic actuators for flexible operation.

Suitable Medium: Ideal for water, steam, gas, oil, and acid-base corrosive mediums, offering versatile performance across industrial applications.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

_1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)