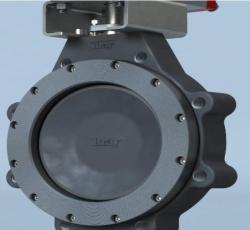

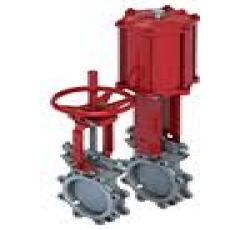

Trunnion ball valves feature a robust design where the ball is anchored by trunnions to prevent axial displacement in the flow direction. As line pressure increases, the seat compresses against the ball, ensuring reliable sealing at the contact surfaces. Standard trunnion construction includes automatic cavity relief to handle overpressure within the valve body, making them suitable for a wide range of applications across all sizes and pressures.

Construction:

- Two or Three Piece Bolted Body

- Port: Reduced bore, full bore, or fully piggable

- Stem Retention: Anti-blow-out stem

- Leakage Rate: ISO 5208 rate A soft seated, rate D metal seated

- Antistatic Device: Electric conductive connection between internal parts and body for anti-static function

- Pressure Relief: Automatic cavity relief (self-relieving seats)

- Sealing: Bi-directional, Double Block & Bleed (DBB) with optional DIB-1 & DIB-2 sealing

- Metal seated with Tungsten or Chrome Carbide coatings

- Primary metal secondary soft (PMSS) with differential hardness

- Soft seated with thermoplastic polymers (Nylon, PEEK, PCTFE), Elastomers (FKM, HNBR, EPDM O-Rings)

- Drain: Drilled and threaded connections for all sizes

- Vent: Drilled and threaded vent connections for sizes ≥ DN150 (6")

- Stem Grease Injectors: Included for all sizes

- Seat Grease Injectors: Included for sizes ≥ DN150 (6")

- Lifting Points: Included for sizes ≥ DN150 (6") or valves of 250 kg min

- Support Feet: Included for sizes ≥ DN150 (6") or valves of 250 kg min

- Stem Extension: Not applicable for this model

- Valve Operation: Lever, Gearbox, or Actuator with position indicator and locking device

- Material Testing: Pressure containing & controlling parts to EN 10204 3.1; Materials in Sour Service according to NACE MR0175, MR0103, ISO 15156; Non-destructive testing (NDT) to API 6D, ASME B16.34

Trunnion ball valves offer exceptional reliability, longevity, and performance across demanding applications including oil & gas, chemical processing, and more. Designed to withstand high pressures and harsh environments, they ensure optimal fluid control and operational safety.

Sign in with Google

Sign in with Google

Sign in with Facebook

Sign in with Facebook

Sign in with Google

Sign in with Google

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.png)

USD or choose a different currency.

USD or choose a different currency._1727168586.png)

) (1)_1727158160.png)

(4)_1729176674.png)